Flavours and Fragrances

Production and use of flavours, fragrances and aromas: precise feeding and easy cleaning

Gericke is a powder handling specialist which manufactures equipment to handle high value powder products even in small quantities. Precise feeding, easy cleaning, and equipment allowing rapid product changes are the main characteristic of the Gericke equipment.

For more information:

InquiryBringing the powder to your reactor

As a powder handling specialist, Gericke is the right partner to bring powder raw materials to the reactor for the production of aromas, flavours and fragrances. Big Bag discharge stations, tipping stations and advanced conveying solutions have been established to bring the powdered starting materials to the reactors. Gericke also offers solutions after the formulation.; e.g. the Nibbler can be used to calibrate the particle size after drying.

Gentle mixing - Efficient sifting

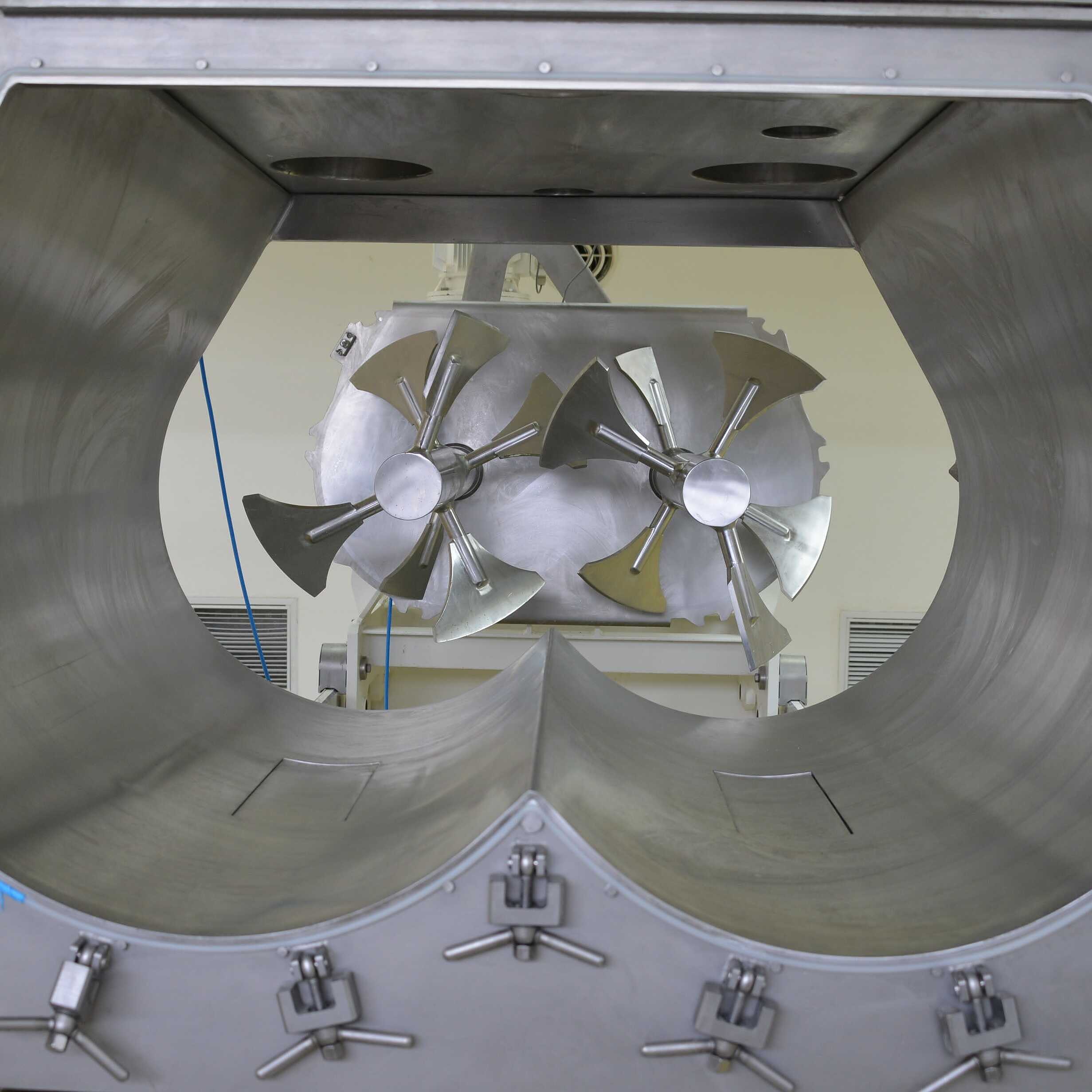

Gericke’s extractable double shaft mixer, GMS ECD, gently handles fragile or pulpy ingredients. Spraying or adding liquid flavours or aromas to a powder carrier material is a standard task for this mixer. Gericke realises this task continuously using the TCM continuous mixing systems and the GCM mixing systems.

Very fine powders tend to be explosive and are often sticky. Centrifugal sifters GS can be used for such difficult and fine materials and can be manufactured for use in hazardous areas.

For more information:

Downloads

Our customers

Leading Edge Powder Processing Technology