Dense Phase Conveying

Efficient material transport whilst preserving quality

Dense phase pneumatic conveying systems for powder transfer are used when the product quality is of the highest importance. They minimise changes in bulk density and particle size distribution and also limit demixing effects, and can be used for many materials such as powders, granules, flakes and pellets.

The absence of rotating parts in pressure vessels reduces maintenance costs. The advantageous ratio of product to conveying gas also makes such systems energy efficient.

For more information:

Inquiry

Absolutely dust tight

Pressure vessels are utilised within dense phase conveying systems to introduce the bulk solids into the pipeline. Contrary to when using rotary valves, the system has no leakage and is absolutely dust tight.

This allows a high pressure range from 1 barg up to 6 barg, or more. The high loading and low velocity lead to gentle conveying and to low wear of both pipeline and receiver.

With dense phase conveying systems, the transport of bulk solids is possible from short distances right up to long distances of several hundred meters.

Your benefits

- Very gentle handling of fragile products

- Minimised wear of pipeline and bends

- Minimised demixing of mixed products

- Absence of rotating parts eliminates the danger of metal contamination and reduces maintenance costs

- Gas and dust tight system with no leakage air

- High solids loading leads to smaller pipe diameter and low gas consumption

- Long conveying distances, up to 500 m or more, and capacities up to 150 m3/h

- Ready to use graphical pneumatic conveying controller, STP 61

Applications

- Gentle conveying of instant products from spray drier

- Demixing free transport from mixer to filling lines

- Direct conveying into process reactors

- Batch weighing with pressure vessel and subsequent full discharge

- High capacity material handling

- Conveying using inert gas option

- Truck or railcar unloading

Specifications

- Pressure vessels according PED 2014/68/EC, ASME and GB 150

- Available in carbon steel or stainless steel

- Available volumes are from 20 l to 5'200 l

- Different executions available to fit various industry’s needs such as food, chemical or mineral

Principle of operation

A pressure vessel is loaded from a silo, big-bag unloader or process equipment, i.e. mixer. The operation cycle includes the refilling, applying of pressure and conveying of bulk material, as plug or layer, to the receiving hopper.

The solids can be conveyed as a continuous layer with the "DenseFlow" PHF conveying system operating at moderate gas velocities of 15-25 m/s.

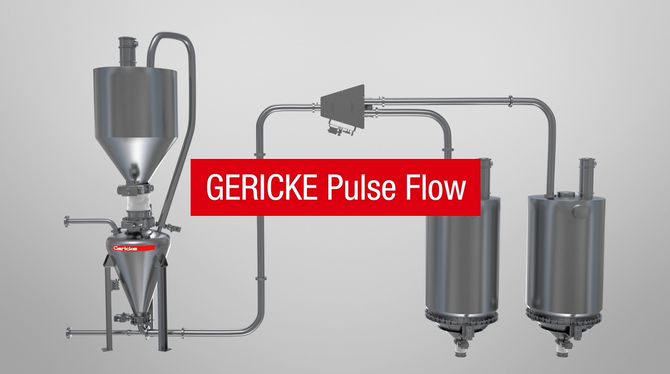

The solids can be conveyed as a pulsed plug with the "PulseFlow" PTA conveying system operating at low gas velocities of 4-12 m/s.

For extended conveying distances and with maximum process safety, the solids can be conveyed as a pulsed plug with the "PulseLine" PTA PL conveying system operating at low gas velocities of 4-12 m/s with the addition of external air injectors equipped along the pipeline.

For more information:

Expertise. Value. Trust.