Loss-in-Weight Feeders: PLC or Dedicated Control Solutions?

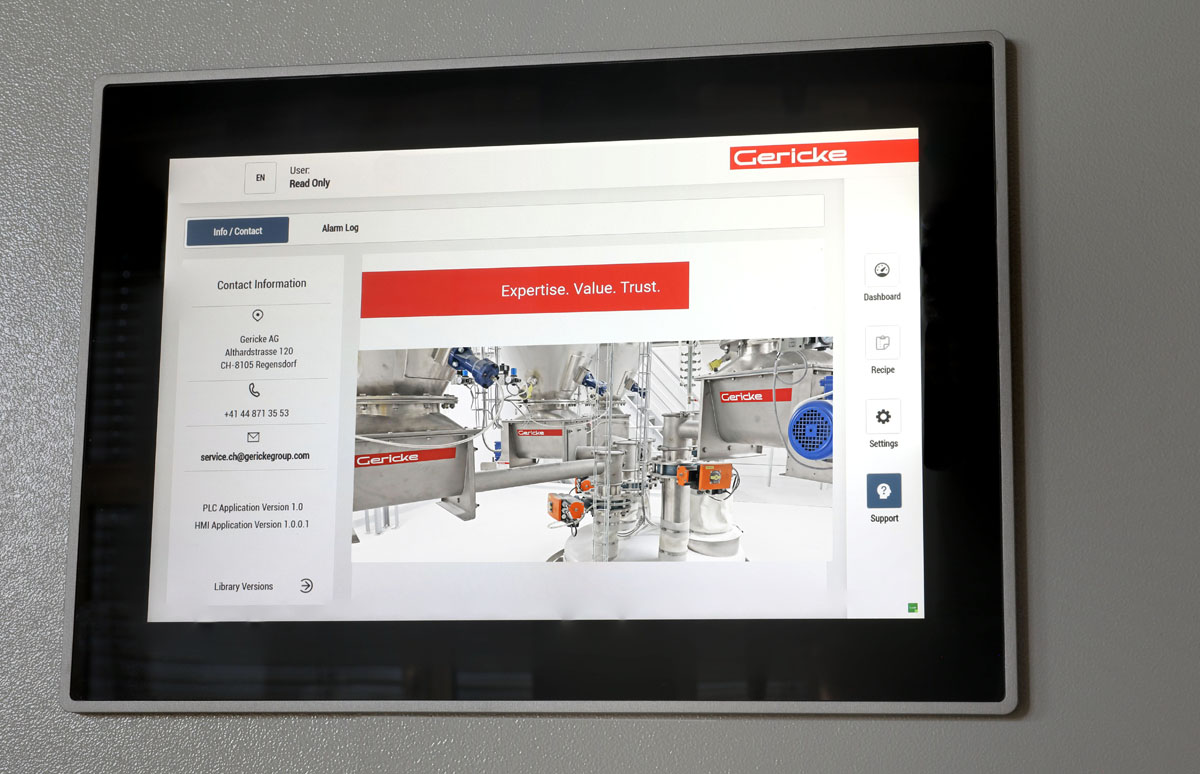

The Gericke GUC-F offers a comprehensive approach to feeding and dosing processes. Unlike PLC solutions, which require separate weighing electronics and programming, the GUC-F combines all necessary components into a single package. This integration simplifies the process setup and enhances overall performance.

When comparing GUC-F to other solutions, several key differences emerge. GUC-F provides extensive service and support for all types of bulk handling applications, whereas PLC solutions lack a dedicated service team for process, dosing, and feeding issues. Additionally, GUC-F excels in the mechanical integration of feeding, dosing, and weighing technology. Most feeders are not stand-alone, and seamless integration into the process is key. GUC-F also features an intuitive modern design for its Human-Machine Interface (HMI), reducing the time needed to read manuals. In contrast, PLC based HMI designs require more time for programming and manual reading.

The GUC-F can control multiple dosing and feeding processes with one controller, with parameters already configured and tested individually with the corresponding loss-in-weight feeders. GUC-F employs sophisticated algorithms to filter out environmental effects, ensuring the best accuracy even under harsh conditions. It supports both analogue and digital weighing cells and different weighing platforms depending on application and accuracy requirements. Furthermore, GUC-F integrates frequency inverters preconfigured, saving time and reducing the need for additional programming.

Another aspect of weighing companies is that they have limited experience with feeding and dosing processes. They do not manufacture or sell feeders and cannot test the complete configuration before shipping and installation. They also lack a dedicated service team for process, dosing, and feeding issues. Gericke, on the other hand, offers a complete package with extensive support for accessories and associated processes.

Cost Comparison: GUC-F vs. PLC Solutions

When it comes to cost, GUC-F offers a more economical solution. The integration of all necessary components into a single package reduces the overall cost of installation and maintenance. Furthermore, preconfigured frequency inverters and support for various technologies minimize the need for additional investments in equipment and training. The extensive service and support provided by the Gericke group also contribute to cost savings by reducing downtime and ensuring optimal performance. With PLC solutions, the need for separate weighing electronics and additional programming increases the total cost.

Fit for Every Application

In conclusion, GUC-F stands out as a superior choice for feeding and dosing technology due to its complete and integrated package, advanced features, and extensive support. Its ability to control multiple processes, sophisticated algorithms, and support for various weighing technologies make it a reliable and efficient solution for bulk handling applications. Additionally, the cost benefits of GUC-F position it an economical and sustainable alternative compared to PLC solutions.