Detergents and Soaps

Handling and processing solutions for the home and body care industries

Products for home and body care, such as detergents and soaps, have very specific demands for tipping, transfer, feeding, mixing and granulation. Raw materials such as soda ash, phosphates, zeolite, sodium sulphate, and calcium carbonate, usually arrive at the production site via big bags or truck. Gentle conveying technology transfer the powders to silos or intermediate hoppers. Tank or big bag unloading, gentle conveying, mixing and spraying of liquids are all part of your reliable and quality assured manufacturing processes. Our solutions prevent the creation of dust during production, and also in the end product.

For more information:

InquiryFor your entire process

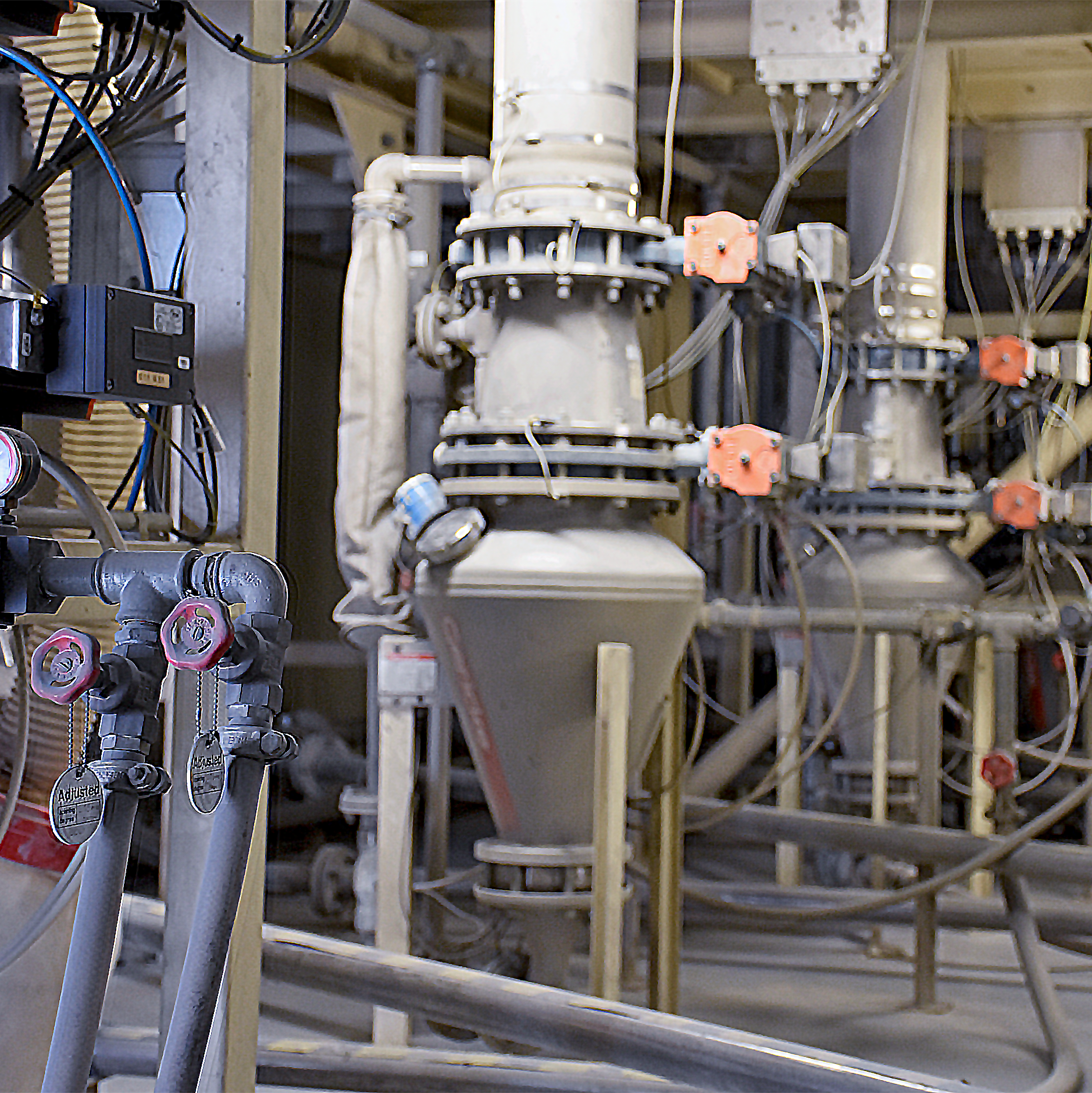

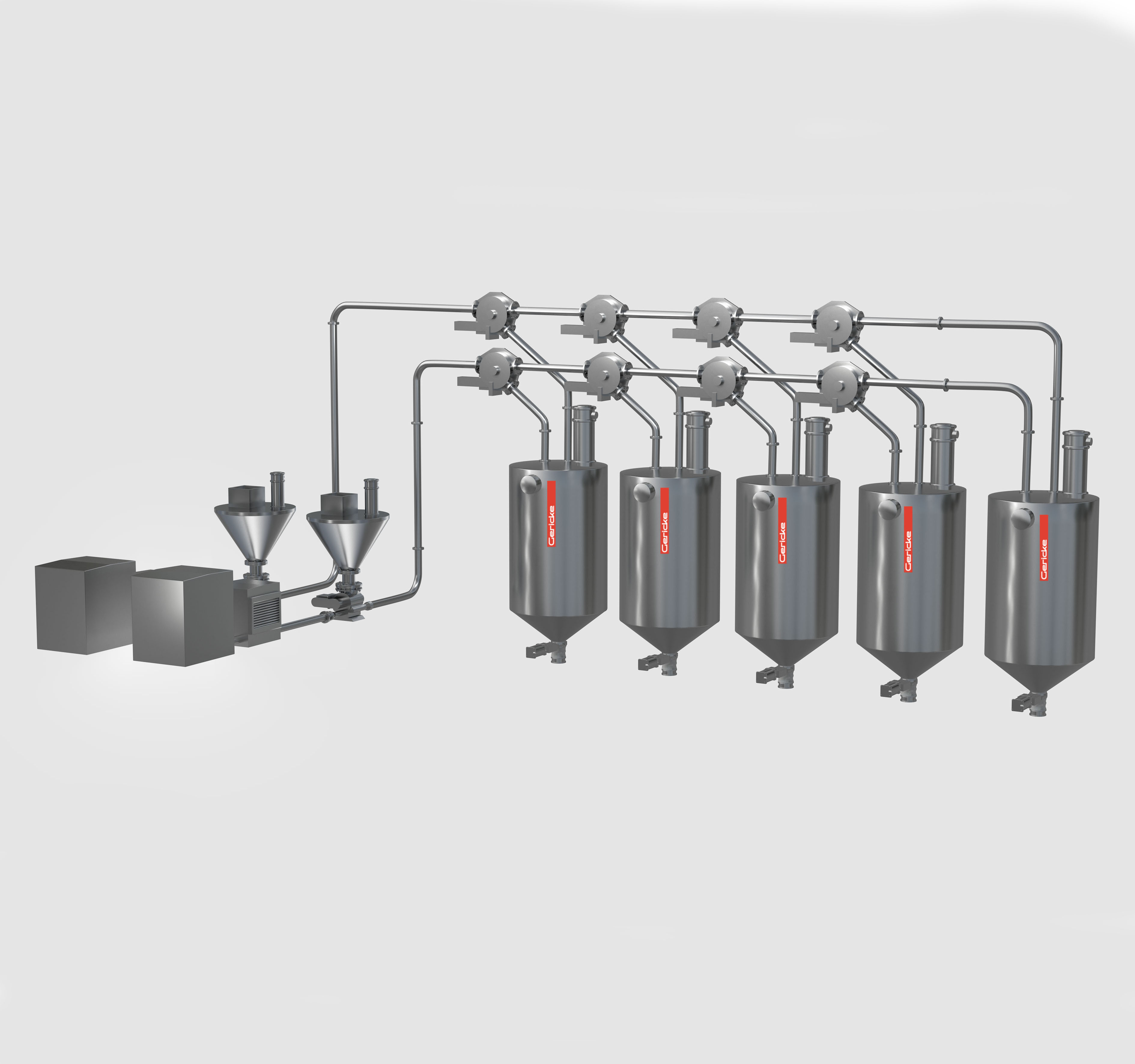

Each customer has its own process flow. Gericke specialises in the raw material reception, storage, silo discharge and recipe preparation. Common to all is the careful handling of the raw material and the correct dosing of additives. Gericke’s conveying technology is gentle and preserves the quality of the raw material from tank unloading through to storage. A unique mobile pneumatic manifold ensures that the conveying velocity between the bulk tanker and the silo is limited such that the characteristics of the granulated raw material are maintained.

The right equipment

Screw feeders or belt weighers are adjusted to the characteristics and particle size of the ingredients. Continuous or batch mixers are supplied for mixing of the starting powders even with challenging liquids as waterglass.

End of the line special compact mixing lines (TCM) have been developed to add fragrances to the product directly just upstream of the packaging or compaction. Our very advanced Gericke pneumatic conveying technology realises reliable transport solution even for soap chips and noodles.

Gericke has specific knowledge for turnkey installations for the production and blending of enzymes. AGV driven recipe management and very gentle batch mixing in a GMS double-shaft mixer allows you to benefit from a state of the art process layout.

Solution Example: Pneumatic Conveying of Soap Noodles

Challenges

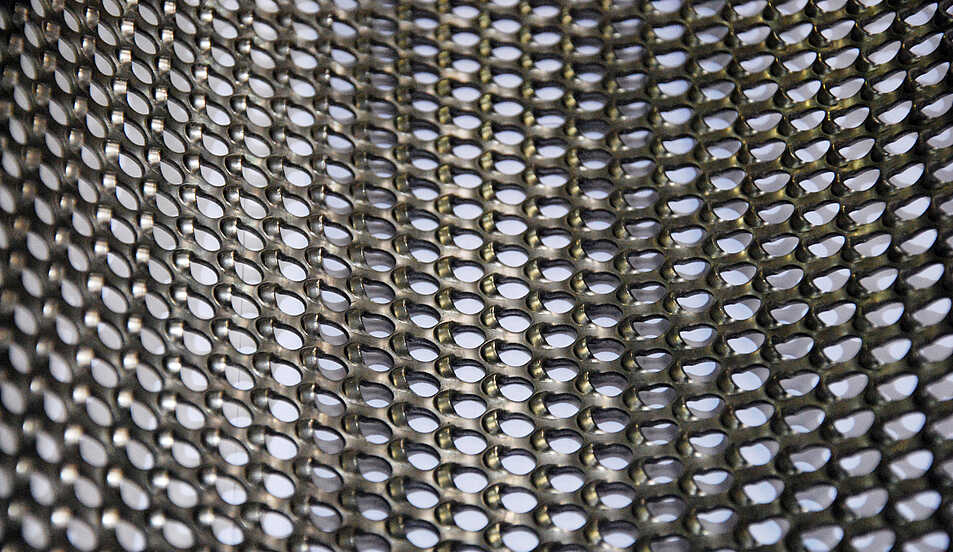

- Very sensitive material, preserving material quality is key!

- High capacity

- Multiple materials, multiple receivers

Solution considers

- Correct conditioning of temperature and humidity

- Proper selection of piping material and layout

Advantages

- Perfect preserving of product quality

- Use of our test centres to exactly design the system to the specific materials

Gericke has realized a number of conveying systems for soap noodles. References are available on request!

For more information:

Our customers

Leading Edge Powder Processing Technology