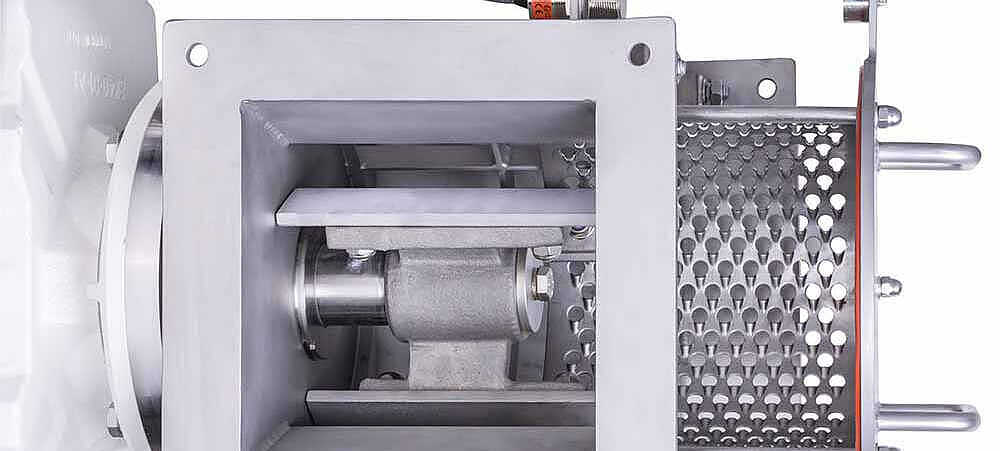

Deagglomerator Nibbler GNB, NBS, NB

Milling, grinding, kibbling, lump and pre-breaking for a wide range of products

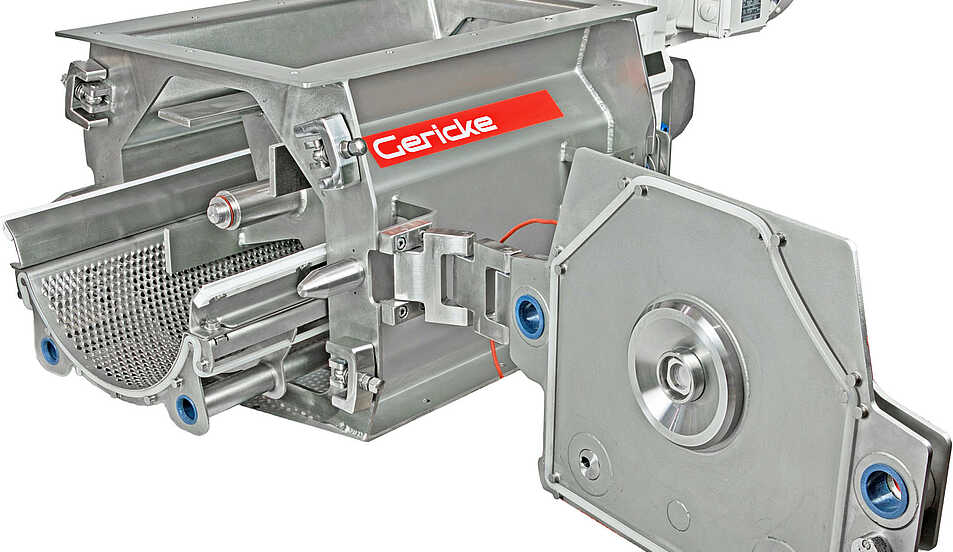

The Gericke Nibbler is a coarse grinder and pre-breaker for the size reduction in a broad range of applications. It is used for de-agglomeration, granulation, milling, rework and size calibration of lumpy or frozen products.

For more information:

InquirySize reduction and deagglomeration

Nibblers are used as part of many processes, often directly integrated into the product stream. Main process uses are:

- Deagglomeration after drying, spraying and mixing etc.

- After storage in silos.

- Below big bag stations, tipping stations, sacks, drums and containers where compaction may occur.

- Before secondary processing including micronizing, milling, grinding and feeding.

- Before pneumatic or mechanical conveying.

- Reprocessing/reclaiming of oversize or off-spec materials.

- After band driers.

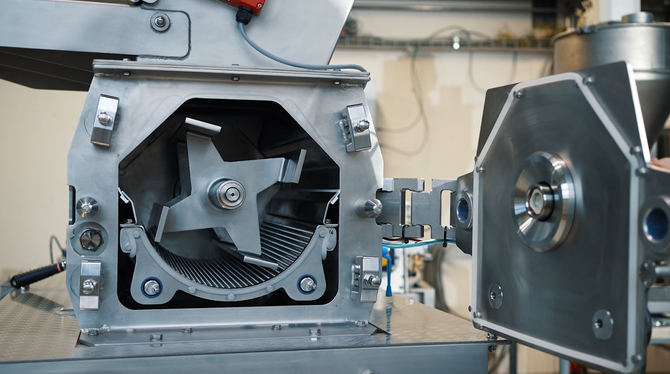

Meet the new GERICKE Nibbler GNB!

- Consistent particle size and high throughput with lower heat generation than traditional grinding solutions

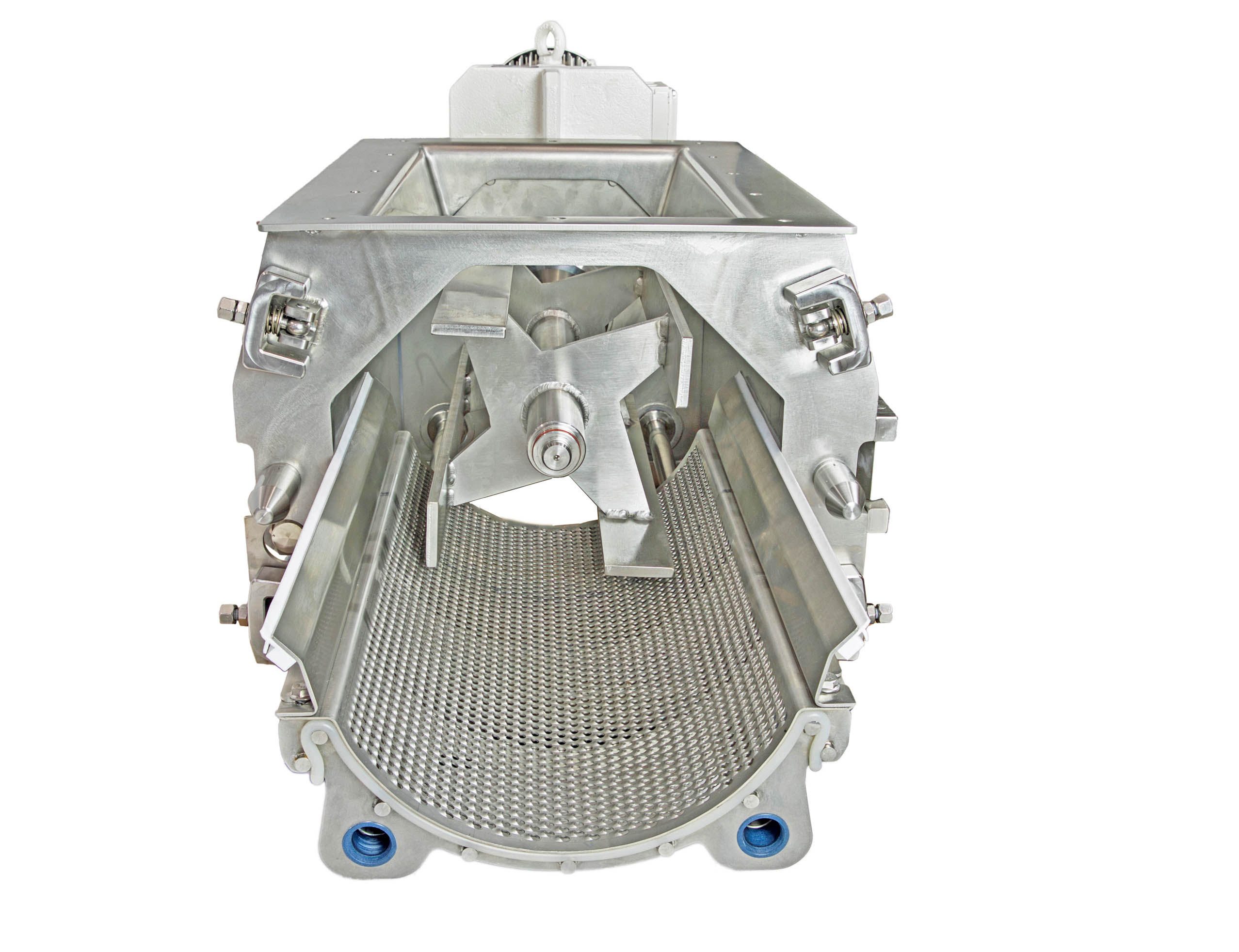

- Very short downtime with easy to clean design features giving full access from both sides with an optional extractable drive

- Features allowing quick inspection and changing of the main screen

- Minimum product temperature rise and fines generation due to low rotational speed and by use of a cutting action rather than creating excess heat by grinding

- Easy adjustment of paddle / cutting screen clearance for maximum process flexibility

- Metal to metal contact detection for maximum process safety (standard with ATEX version)

- EHEDG design conformity, wash-out and wash-in-place seals

- ATEX versions for gas and dust environments (also combined)

- Highly efficient, low power consumption and low noise emission levels

Your benefits with all our de-agglomerators and lump breakers:

- Compact and robust design but high capacity size reduction.

- Low power consumption and low noise levels.

- Minimum product temperature rise and fines generation, due to low rotational speed.

- Consistent particle size.

- No special tools required for maintenance, easy to access.

- Adjustable paddle blades.

- Customized versions available for special applications (heating/cooling, higher pressure, heavy duty etc).

Specifications

- Available in sizes from 200 mm up to 1200 mm, for process rates from less than 10 kg/h up to 50,000 kg/h.

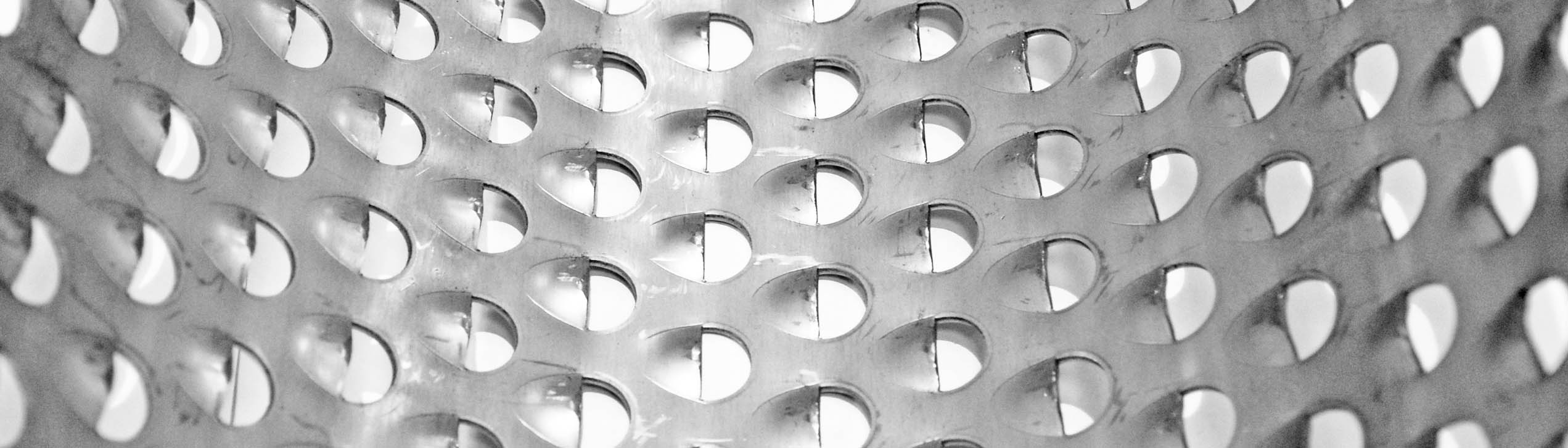

- Screen sizes from 1 mm to 25 mm.

- Screen materials perforated plate/serrated/woven wire.

- Optionally ATEX approved.

- Hygienic options.

Nibbler 800 mm

For more information:

Expertise. Value. Trust.