System Retrofits

Make your existing production future-proof!

Gericke installations have a very long service life. But new technologies, regulations, energy saving goals or new production requirements can still make it necessary to modernise a system. Gericke is your competent partner for bringing your system up-to-date.

Safe and compliant

Many requirements for explosion protection, occupational safety and environmental protection have changed over the years. Sometimes internal regulations can no longer be fulfilled with old systems.

With a retrofit, you can bring your installation back up to the latest technical standard to protect your employees, the environment and your reputation.

Efficient and sustainable

Many processes can be realised more efficiently today. New drives, online sensors and control systems increase the energy balance and yield. Maintaining existing process hardware also improves the environmental balance of your existing system.

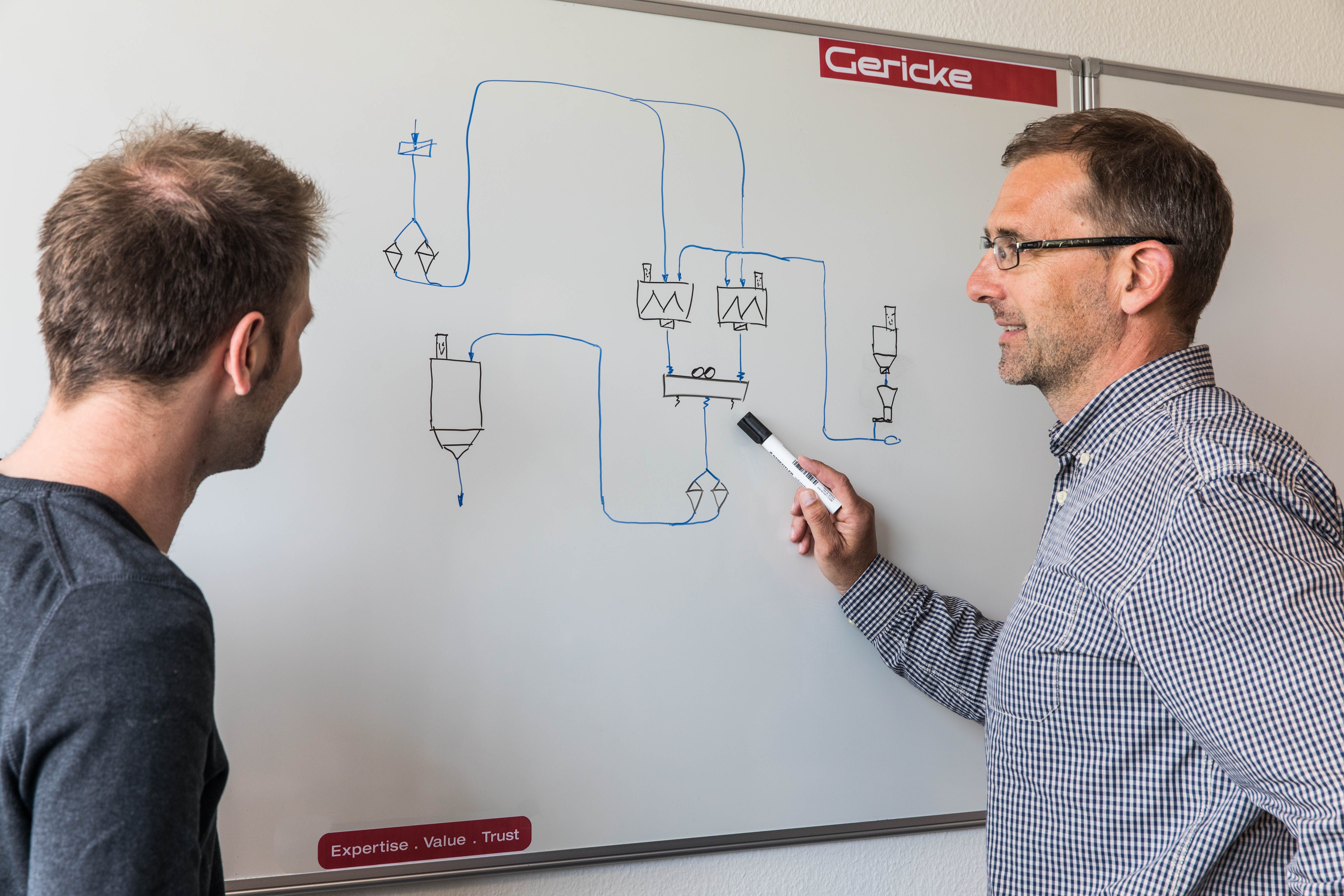

Analyses of the existing situation

Gericke not only offers a complete range of solutions for bulk solids handling, but also provides expertise in automation, plant safety and engineering. With this holistic approach, a comprehensive analysis of the installation can be provided.

Identification of retrofit opportunities

Based on your current situation, areas are identified where existing systems and equipment can be improved through retrofitting. This includes, for example, updating control systems, improving energy efficiency, adapting to new environmental and safety standards or implementing new technologies to optimise your processes.

Definition of customised retrofit solutions

After identifying the possibilities, specific retrofit packages are developed. These include updating existing systems with newer technologies, integrating automation and control systems or expanding functionality to increase performance and efficiency. Trials in one of our test centres help to define the best technical solutions.

Downloads

Leading Edge Powder Processing Technology