Steel

Steel production and flue gas treatment

Gericke is the right partner for sack tipping, conveying and feeding of additives for the alloy and steel production as well for flue gas.

For more information:

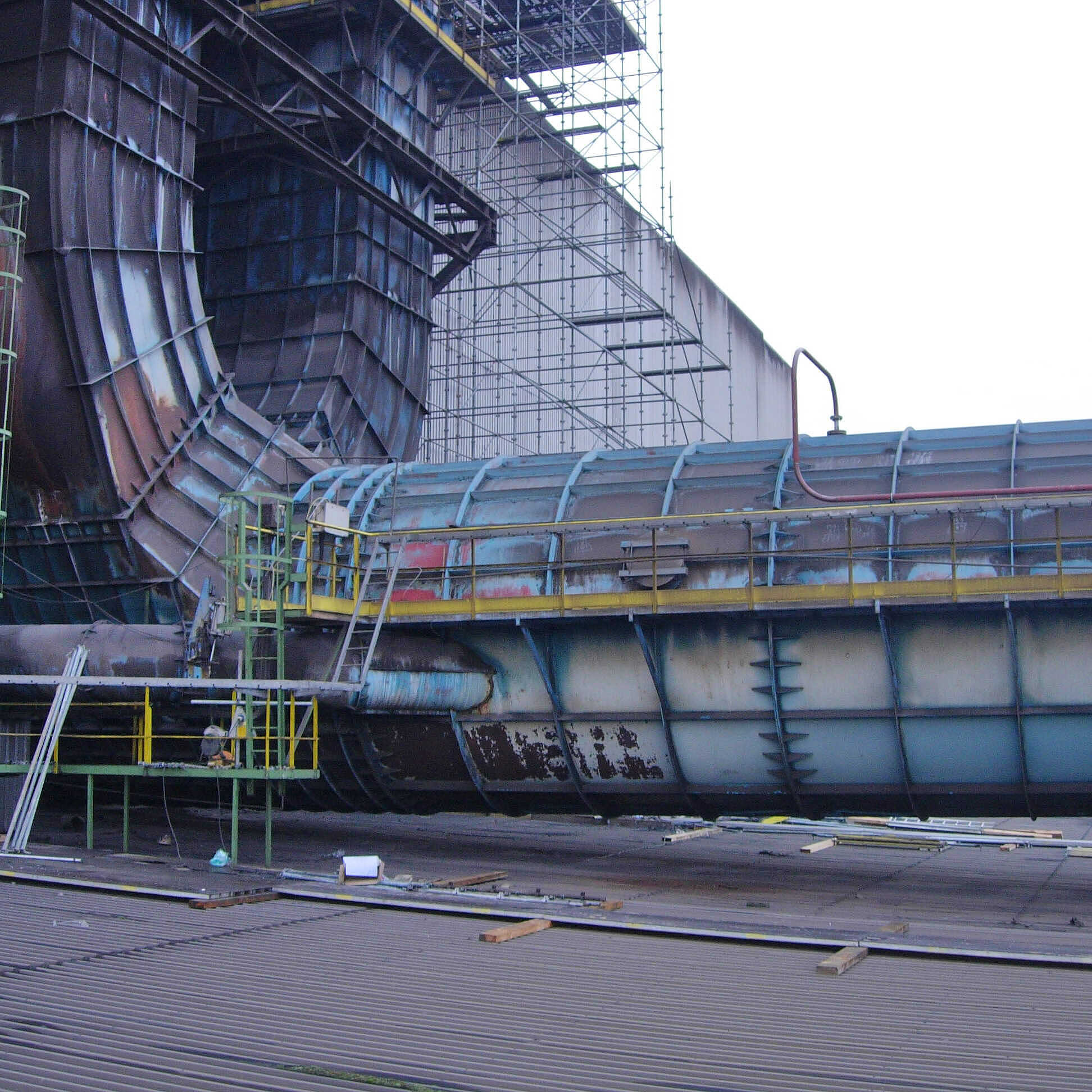

InquiryIt’s a tough world

Harsh manufacturing conditions require well designed and virtually indestructible equipment. Gericke is well known for the outstanding robustness of our tipping stations and feeders. State of the art continuous feeding and conveying allow the most modern production of high-performance alloys such as used in the car industry. We have unique references for continuous gravimetric dense phase conveying of powders which enable a very controlled powder flow into the melt.

Gericke tipping stations and feeders are used to dose all ingredients before the molding process. Our equipment resists the high ambient temperature. We use our slow velocity dense phase positive pressure conveyor for the gentle transport of the various powders, which preserves the powder characteristics.

Flue gas treatment for a better environment

Flue gas treatment with Powered Activated Carbon (PAC) ensures the fulfillment of legal requirements regarding toxic residues and contributes to achieving an ecofriendly incinerator. The reduction of pollution is achieved by flue gas by injecting PAC.

We supply a fully automated system for this purpose, allowing the exact control of the PAC feed and delivering the data required for your records and documentation.

For more information:

Downloads

Our customers

Leading Edge Powder Processing Technology