Batch Mixer GMS Double Shaft

Superb homogeneity, gentle and hygienic

The GERICKE GMS Multiflux® batch mixer achieves a maximum degree of homogeneity and preserves high-quality ingredients during the mixing process. When the mixing of fragile products, the efficient distribution of micro ingredients, the optimal dispersion of liquids onto particles or the highest hygienic requirements are your challenges, then the GMS Multiflux batch blender is your best choice.

For more information:

InquiryShort mixing time

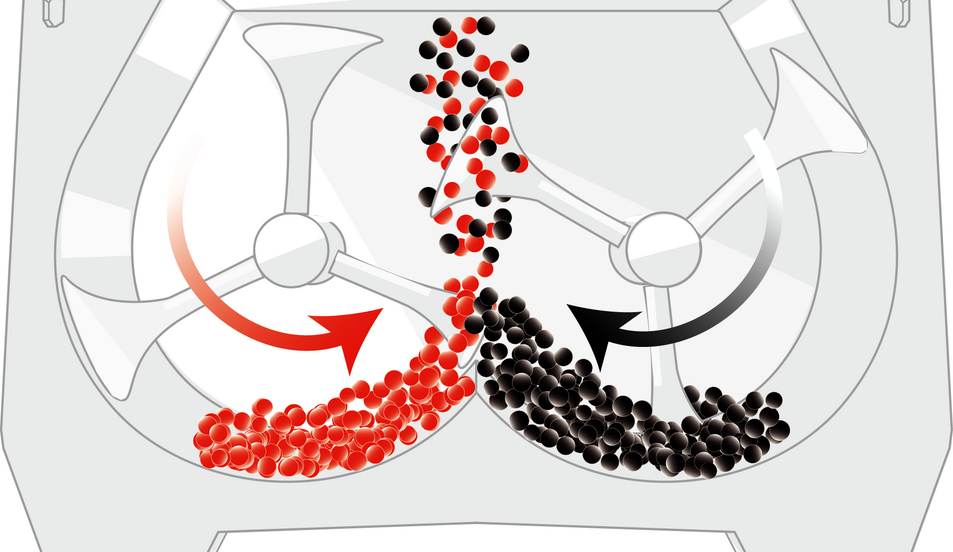

Gericke batch mixers GMS Multiflux® form a mechanical fluidised zone by using two horizontally arranged superimposed counter-rotating mixing tools. This design enables extremely high radial and axial transfer rates, resulting in the highest homogeneity. The mixer operates at the optimal Froude Number of 1.1, where the centrifugal forces exceed gravity forces. Mixing is realised efficiently in short cycle times but with gentle handling for sensitive products.

Gericke GMS mixers can produce up to 16 mixing cycles per hour and are available in sizes of 100 to 4000 litres (useable volume) per batch. The standard cantilevered design of the GMS mixer allows optimal access for the operator via a huge swiveling front door. This door gives full access to the mixing chamber for inspection and cleaning.

Highly flexible

For dispersion of viscous liquids or deagglomeration of lumps, fast rotating dispersion tools can be integrated into the front door. This position allows the use of large diameter dispersers, which are optimally positioned in the product flow and are easy to inspect via the door.

The extractable versions of the GMS mixers have been developed for short time interval validated dry cleaning procedures, even for allergens or flavours. The complete mixing tool can be rapidly extracted from the chamber on rails, using minimal handling effort.

Whenever space is at a premium, then batch mixer Multiflux® GMS C mixers offer more possibilities for the complete application design.

Your Benefits

- Optimal homogenous mix quality is achieved within a short operation time, even for micro ingredients.

- Gentle mixing of sensitive materials.

- Advanced hygienic extractable execution available which meets stringent hygiene requirements following EHEDG and GMP guidelines. This execution allows fast dry cleaning operation.

- Efficient distribution of liquids onto particles and deagglomeration of lumps with optional dispersing tools integrated in the front door.

Applications

The GMS mixer is the standard mixer in infant formula production since this industry has highest demands on mix quality, hygienic design due to stringent requirements of avoiding any cross contaminations. Production capacity is depending on the automatic recipe preparation which is another field of expertise of Gericke. Rates up to 12 t/h per have been realized.

Due to its features GMS is used as well in other food applications like beverages, coffee mixes, breakfast cereals. In chemical industry mix quality even for trace ingredients or liquid addition are required. The adsorption of liquids into silica, the mixing of powder coatings upstream extrusion is a typical field of application.

The dispersing cutter GMS has been patented and is excellently suited to distribute even high viscous liquids in fine powders.

For more information:

Expertise. Value. Trust.