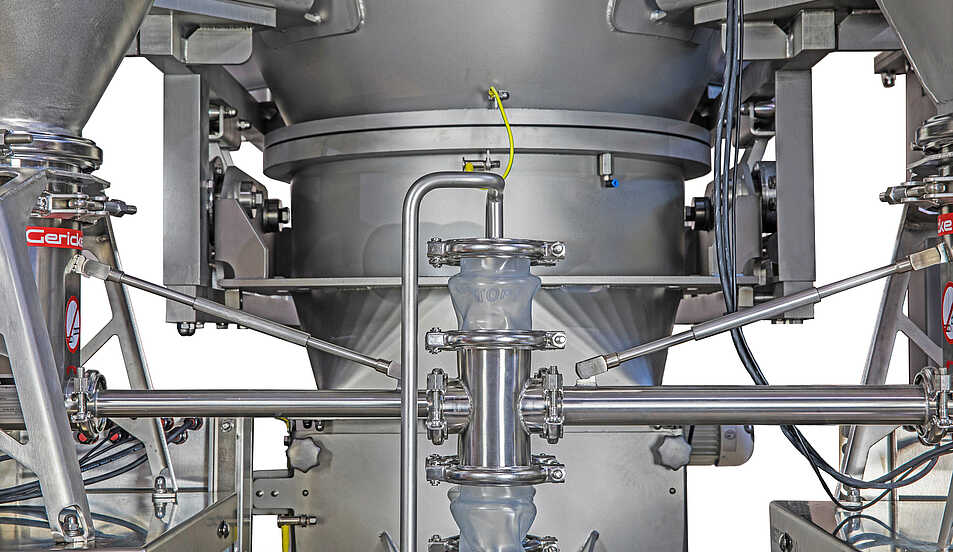

Turbo Compact Mixing TCM

Compact inline mixing for late product differentiation

Cleaning of powder mixing installations may become a time consuming and therefore costly exercise if, for example, flavours, aromas, cocoa or bacteria are contained in the recipe. The Turbo Compact Mixing module, TCM, has been developed as a compact inline mixing module to be installed directly upstream of filling, packaging or processing equipment. It minimises equipment surfaces and thus saves time for cleaning and massively increases productivity.

For more information:

InquiryYour Benefits

- Inline gravimetric continuous feeding and mixing system with guaranteed trueness of recipe.

- Flow rate of each ingredient is guaranteed by Gericke’s advanced loss-in-weight feeder controllers in combination with very accurate weighing.

- Space (height) savings thanks to very compact integration of feeding and mixing.

Fast, safe, easy to clean

- Fast and gentle mixing.

- Minimal equipment to clean, excellently suited for products which must guarantee zero cross contamination.

- Allergen handling – down time due to dry cleaning is reduced by 90 %.

- Complete disassembly: Even the very compact mixing chamber is removable and so allows for fast and easy cleaning.

Feeder in cleaning position

Easy access for cleaning to all areas

Applications

- Continuous inline mixing of a principal component stream with up to 3 minor streams.

- High capacity for up to 20’000 l/h.

- End of line addition of critical products upstream filling or extrusion line ; e.g. flavours, colourants.

- Minimal height for the addition of minor ingredients with frequent changes, ideally suited for flavours, colourants and allergen handling.

- Inline operation with downstream filling lines (e.g. bags, sachets, cans, capsules), compaction or processing lines.

- System is validated even for frequent start- stop operation.

For more information:

Downloads

Expertise. Value. Trust.