Heavy Duty Rotary Valves

From hygienic to extra heavy duty

Rotary valves are a common product in many powder handling applications. RotaVal products combine the expertise from a dedicated valve manufacturer with the global experience from many successful installations.

Contact us!

You want to know more about our products and services?

T +44 1249 651138

sales.rvgerickegroup.com

spares.rvgerickegroup.com

Applications & Industries

Thanks to its highly modular design, our rotary valves can be adapted for virtually all types of product characteristics and applications:

- Metering device

- Airlock, explosion containment, flame barrier and system isolation

- Suitable for gravity, positive pressure and vacuum conveying systems

- Powders, granules, pellets, grain, feed and chips

The RotaVal airlocks are used in many different industries, such as dairy, food, pharmaceutical, minerals, plastics, power plants and others.

Rotary Valves - Heavy Duty HDM

The HDM airlock is our general purpose rotary valve line, able to cover many standard applications.

The HDM rotary valve has been designed using finite element analysis to make the housing even more robust.

Rotary Valves - Heavy Duty Cleanable HDMC

The HDMC rotary valve is a cost effective solution based on the HDM valves for occasional cleaning of the valve internal.

The non-drive end cover can be quickly removed to gain access for cleaning which can be carried out by plant operators without the need for special tools.

Various standards of finish are available to suit most hygienic applications.

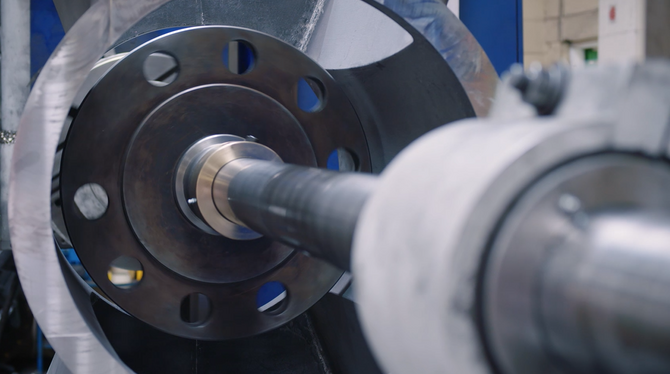

Special Designs and Sizes up to 1200 mm

The design and manufacturing of rotary valves beyond the commonly used sizes and shapes is a challenge to many manufacturers. For those applications requiring large throughputs or handling large size particles, for example in chemical and aggregates industries, this is not the case for Gericke RotaVal.

With in-house development and production equipment Gericke RotaVal has experience of building valves up to sizes of 750 by 1200 mm, often with special coatings.

We also manufacture offset valves or special flange connections. Talk to us to learn more about our flexibility!

Rotary Valves - Extra Heavy Duty EHD

The Gericke RotaVal EHD units have been well-proven over many years and are widely used in discharging under adverse pressure conditions, materials such as cement, PFA, granite dust, silica sand, mineral powders etc.

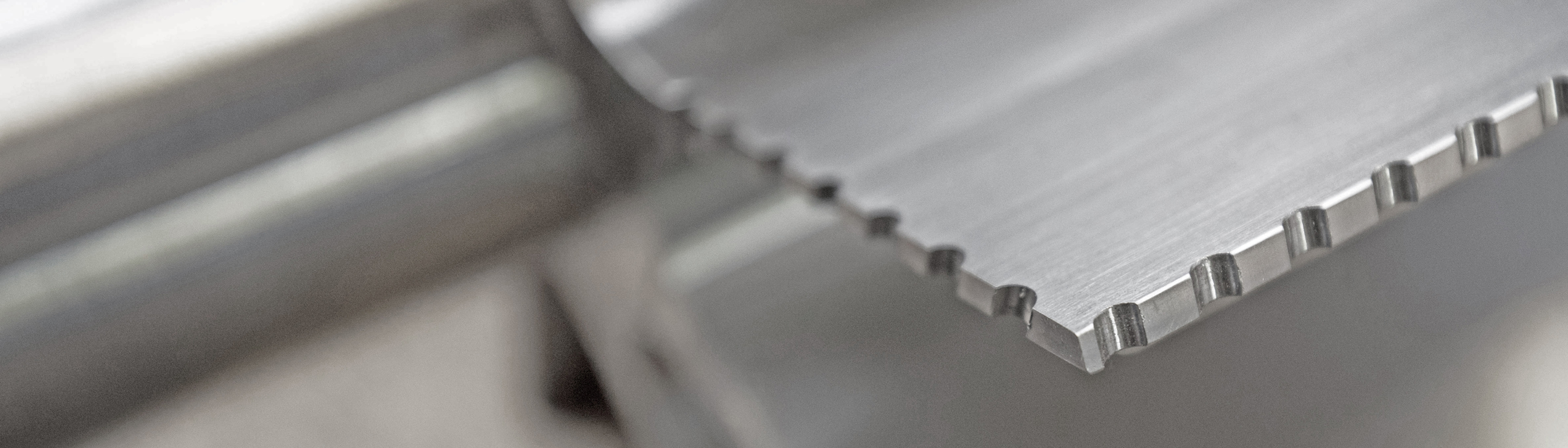

- Replaceable internal components allow for on-site refurbishment.

- Standard valves manufactured in cast iron / SG iron / carbon steel construction with round flange. To further enhance durability replaceable body liner can be hard chromed or ceramic coated.

- Rotor shaft sealing options include various types of gland packing, mechanical seals, air or grease purge.

NOTE: Service life of these valves will vary according to the service conditions prevailing. Selection must be undertaken with care and system conditions where possible adopted to ensure maximum service life.

Your advantages (depending on version)

- Highly configurable to suit virtually all applications

- Valve housings are individually pressure test for 10bar(g) explosion and flame containment requirements

- Unique replaceable parts for wear including rotor shaft, line, blades, end discs and sleeves

For more information:

Expertise. Value. Trust.